SERVICES WE OFFER

Going Beyond Basics: Custom Tools, Redressing Services, and Expert Training for the Stone Industry

CUSTOM DIAMOND TOOLS

We proudly offer a bespoke “Tailor-Made Tools” service, enabling us to supply custom tools meticulously crafted based on customer specifications and drawings in any dimension, profile, technology, or diamond grit. Whether you’re undertaking a high-end project that demands intricate profiles—such as bamboo effects, complex geometries, or other detailed designs—our experienced team is dedicated to bringing your vision to life with precision and artistry.

Simply send us your drawing, and we will deliver a detailed mock-up of the custom profile tool for your approval, ensuring that every aspect aligns perfectly with your expectations. Our commitment to quality means we take the time to collaborate with you, refining designs until they meet your exact needs.

In addition to our standard offerings, our expertise extends to creating custom profiling tools for a variety of machines, including handheld devices, bridge saws, and CNC machines. These bespoke tools are engineered for exceptional performance, ensuring precise profiles and faster results, which ultimately guarantee that your projects adhere to the highest standards of quality and efficiency.

Our goal is to provide you with tools that not only meet your technical requirements but also enhance your overall workflow. To get started, simply use the Contact Us button below to find our email address. Send us a comprehensive description of the type of tool you require, along with any specific details or a drawing of the desired profile. We will respond promptly with a detailed digital drawing for your review and approval.

Experience the difference that personalised service and expert craftsmanship can make in your stone projects. Let us partner with you to transform your ideas into reality.

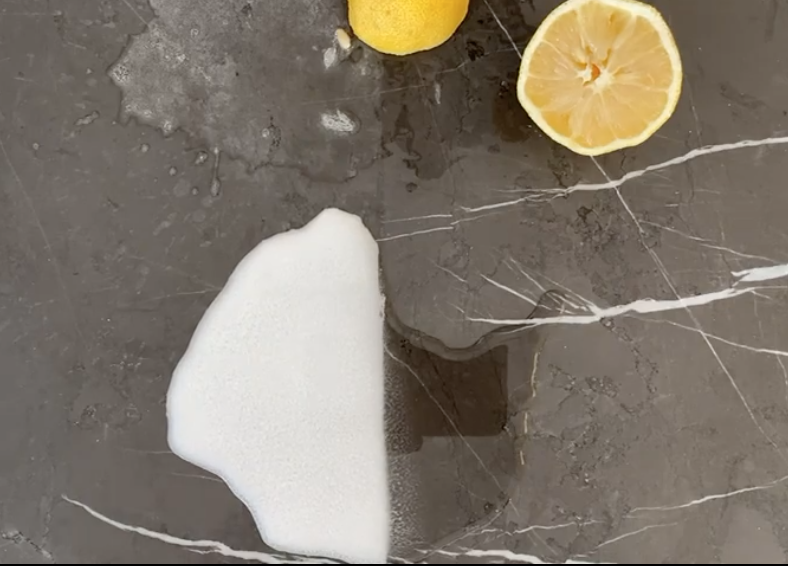

SAFE MARBLE: The Ultimate Acid-Proof Protector for Marble and Terrazzo Surfaces

Overview: SAFE MARBLE is a revolutionary acid-proofing protector specifically designed for marble and terrazzo surfaces. It effectively shields these surfaces from the corrosive effects of common food substances, including lemon juice, wine, fruit juices, soft drinks, and even soaps and perfumes.

How It Works: SAFE MARBLE creates an imperceptible protective coat that covers the surface’s porosity, acting as a barrier between acids and the underlying material. Its unique composition ensures that it remains clear and does not yellow when exposed to UV rays, preserving the natural beauty of the marble. Most marble types retain their original colour after treatment, while surfaces become both water and oil repellent, enhancing durability.

Comprehensive Training Program: To ensure optimal results, we provide extensive SAFE MARBLE training that guides you through the entire process of achieving acid resistance. Our training includes:

- Surface Preparation: Learn how to properly grind and repair surfaces before application.

- Treatment Application: Step-by-step instructions on applying SAFE MARBLE.

- Curing Process: Understand the necessary steps for effective curing.

- Finishing Techniques: Techniques for hone finish sanding and polished finish sanding.

- Maintenance Guidance: Best practices for maintaining treated surfaces.

- Hands-On Exercises: Engage in practical repair exercises to solidify your learning.

Flexible Training Options: We offer customisable training dates that can be scheduled to fit your needs. Contact us for more information on available sessions.

SAFE MARBLE Features and Benefits

- Anti-acid Protection: Shields surfaces from acid damage caused by common food substances.

- Anti-Stain Formula: Effectively prevents stains from food, drinks, and other contaminants.

- Anti-Oil Properties: Resists oil penetration, keeping surfaces clean and free from greasy marks.

- Water-Repellent: Forms a barrier that prevents water absorption, enhancing surface longevity.

- Non-Peeling Layer: Creates a durable finish that does not peel or flake over time.

- UV Stable: Will not turn yellow when exposed to sunlight, maintaining a clear appearance.

- Proven Stability: A reliable product that has been on the international market since 2014, with 10 years of tested performance—no surprises or instability.

- Versatile Application: Can be applied both before or after installation, providing flexibility for various projects.

- Extended Workability: Remains workable for hours, allowing ample time for application.

- Food Contact Certified: Safe for use on surfaces that come into contact with food, ensuring health and safety.

- Ideal for Countertops: Perfectly suited for kitchen and bathroom countertops, enhancing both durability and aesthetics.

- Dirt Resistance: Reduces the accumulation of dirt, keeping surfaces cleaner for longer.

- Limits Absorption: Minimises the absorption of inks, writings, and sprays, making maintenance easier.

- Simplified Cleaning: Makes cleaning surfaces easier and more efficient, saving time and effort.

- Reversible Treatment: Can be removed without grinding, allowing for easy corrections or updates.

- No Special Tools Required: Easy to apply without the need for specialised machinery or tools, making it accessible for various users.

Experience the transformative benefits of SAFE MARBLE and protect your surfaces like never before. Contact us today to schedule your training or enquire about our anti-acidity product range!

CNC TOOL REDRESSING SERVICES

We provide CNC tooling redressing services to ensure your sintered tools remain in excellent condition. Your tools will be sent to our CNC specialist in Italy, where the redressing process will be expertly performed. After the work is complete, the tools will be returned to us, and we’ll promptly send them back to you. When you receive your tools, they will look as good as new!

You’ll find that our redressing services are a far more economical choice compared to purchasing new tools.

You might wonder why you should consider redressing your tools. Here are some compelling reasons:

- Maintain Precision: Over time, tool wear can lead to reduced accuracy. Redressing helps restore the original geometry, ensuring consistent cutting performance.

- Improve Surface Finish: Worn tools can produce rough surfaces. Redressing enhances the tool’s edge, leading to better surface quality on the machined parts.

- Extend Tool Life: Regular redressing can prolong the life of your tools by removing worn areas and maintaining optimal cutting conditions.

- Reduce Downtime: By keeping tools in good condition, you can minimize unexpected breakdowns and production interruptions.

- Cost Efficiency: Instead of constantly replacing tools, redressing can be a more economical option, allowing for better resource management.

- Enhanced Performance: A well-maintained tool operates more efficiently, which can lead to faster machining speeds and improved overall productivity.

- Consistent Results: Redressing helps achieve uniform results across multiple parts, which is vital for maintaining quality standards in production.

Redressing CNC tools is a key practice for ensuring efficiency, quality, and cost-effectiveness in machining operations.

If you’re interested in our tooling redressing services, please fill out the contact form below. Be sure to provide a detailed description of your tools so we can assist you effectively.

Once we receive your request, we’ll provide you with a quotation, estimated lead time for redressing, and delivery details. We look forward to helping you keep your tools in top condition!